Case Study 2000-2007. Research Project AHMOS

Client

8-Nation collaborative projects AHMOS and AHMOS II (Active Health Monitoring System)

AHMOS: BAE Systems / QinetiQ / Smart Fibres (UK); EADS-DASA (Germany); Patria Finavitec Oy / VTT Manufacturing Technology (Finland); Stork Fokker Services / National Aerospace Laboratory (Netherlands); Alenia Aerospazio / Centro Italiano Ricerche Aerospaziali (Italy); EADS-CASA / Instituto Nacional de Téchnica Aeroespacial / UPM (Spain); DEMEX Consulting Engineers AS / Risø National Laboratory (Denmark); Centre Spatial de Liège (Belgium)

AHMOS II: BAE Systems, QinetiQ, EADS – DASA, Patria Finavitec Oy, VTT Manufacturing Technology, Emmecon Oy, Stork Fokker Services, National Aerospace Laboratory, Alenia Aerospazio, Centro Italiano Ricerche Aerospaziali, EADS – CASA, Instituto Nacional de Technica Aeroespacial, Universidad Politecnica de Madrid, DEMEX Consulting Engineers AS, Risø National Laboratory

Challenge

AHMOS: To define, develop and demonstrate practical Structural Health Monitoring systems able to reduce the cost of ownership of military aircraft or other military platforms by reducing inspection and maintenance costs.

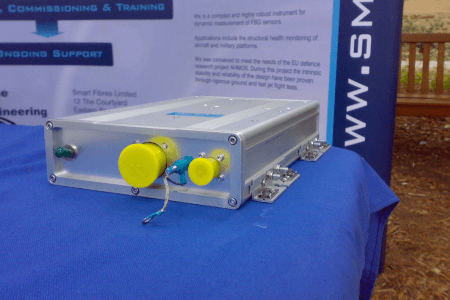

AHMOS II: To develop a flight-worthy interrogator as Smart Fibres’ contribution to a EU funded consortium to demonstrate practical Structural Health Monitoring systems able to reduce the cost of ownership of military aircraft or other military platforms.

Resolution

AHMOS: The AHMOS project set out to integrate numerous candidate sensor technologies (acoustic emission, FBG, strain gauge, lamb wave, modal analysis, wide-area imaging) into an integrated health monitoring system. Each sensor sub-system communicated structural integrity and damage detection information over a CANbus network to a central processing unit which managed the information for presentation to maintenance crew. During the project, the technology readiness level (TRL) of each candidate sensor technology was increased via trials carried out on ground based test structures.

In Smart Fibres’ system, FBG were evaluated on two structures; a Eurofighter pylon housing box and a Fokker 100 fuselage panel composite repair patch. On both test benches, damage was induced and the FBG data were interpreted as indicators of damage. As damage occurred in the vicinity of the Smart Fibres system, it was identified accordingly.

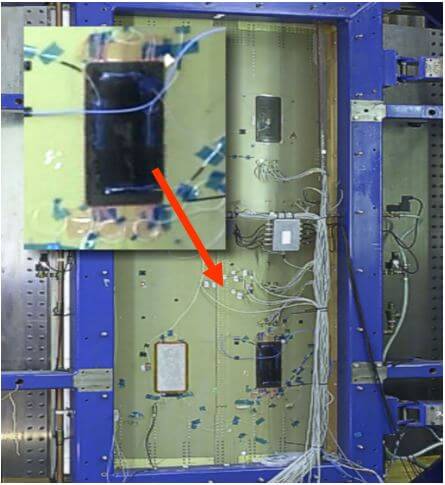

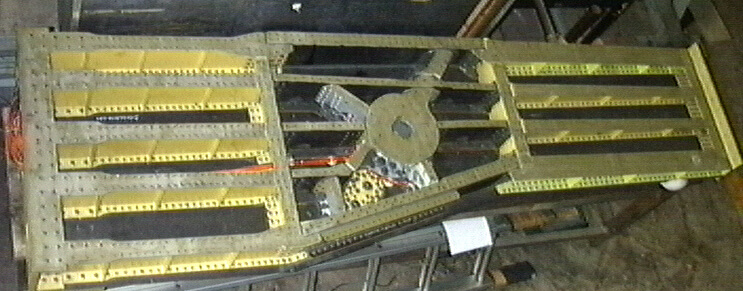

Fokker 100 fuselage panel instrumented test structure

Eurofighter pylon housing box instrumented test structure

In a parallel development, Smart Fibres’ OFSSSI instrumentation was miniaturised and ruggedised as a step towards a flightworthy interrogation system.

As a result of this work, Smart Fibres’ technology was given a TRL rating that permitted its downselection to a follow on project AHMOS II (2004-2007), in which developments towards flying test bed evaluation of the downselected technologies is underway.

AHMOS II:

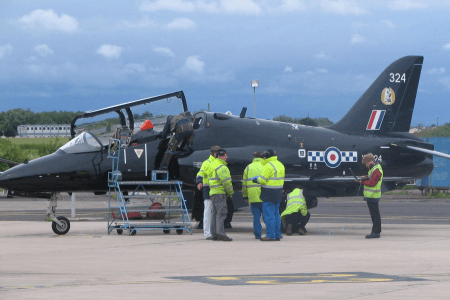

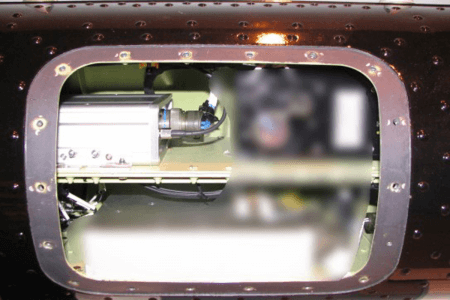

An interrogator with a data acquisition rate of 2.5 KHz and a measurement repeatability of approximately 2 microstrain was successfully demonstrated during multiple flight trials on a BAe Systems hawk trainer aircraft.

The instrument managed to pass a series of demanding ground and flight tests. The flight tests simulated combat manoeuvres, with the instrument pod being subjected to accelerations as high as 9g.

The Wx instrument was assessed to have achieved a technology readiness level of 7 by AHMOS consortium

Images Below:

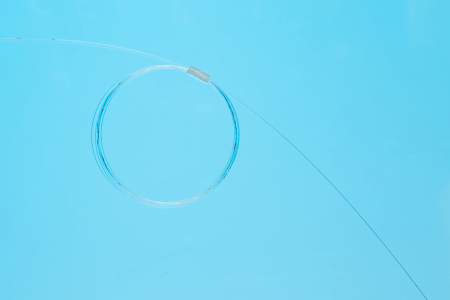

Top left - Preparation for flight test.

Top Middle - Hawk Trainer Jet

Top Right - Instrumentation Pod Pod with fiber optic interrogator

Lower Left - Interrogator prototype