Case Study 2017. Research Project BladeSave

Client

BladeSave is a European Project co-funded by the Horizon 2020 programme.

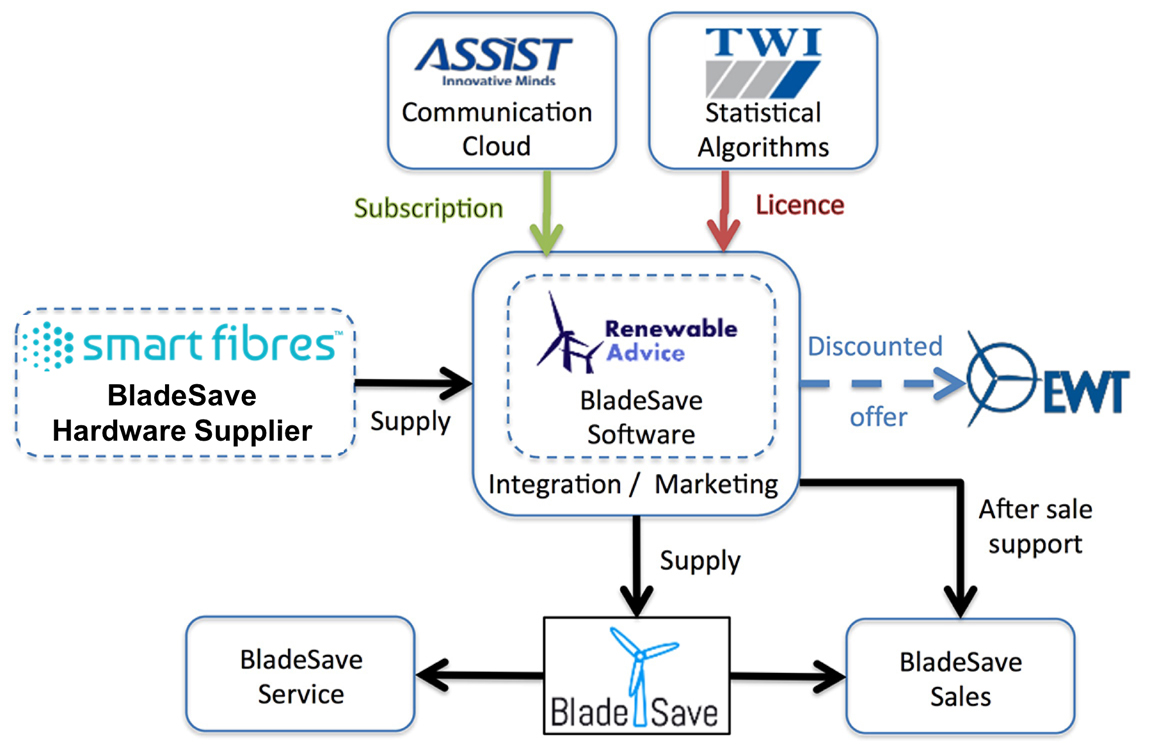

Project Consortium:

- Smart Fibres Ltd

- EWT

- TWI

- Assist

- Renewable Advice

Challenge

Annual wind power installations in Europe have increased over the last 14 years at a compound annual growth rate (CAGR) of 9.8%.

Reliability of wind turbines is a pre-requisite to ensure the healthy growth of wind energy and ensuring the integrity of blades in the wind energy industry is a key issue with respect to the business, safety and the environment.

Turbine manufacturers confirmed the industry need for a condition monitoring system capable of detecting and predicting failures and conditions related to the blades on megawatt-class wind turbines.

According to life-extension programs, with the installation of new and additional condition monitoring equipment around 90% of turbines can potentially carry on working for up to a decade beyond their original 20-year stated operational life.

“Therefore the overall problem envisaged is the lack of an effective and comprehensive condition monitoring systems (CMS) for wind turbine blades. The main issues are:

- Most wind turbines of +2MW are designed with Wind Turbine Condition Monitoring Systems (WTCMS). However, the systems traditionally available on wind turbine blades are based on conventional non-fiber optic sensors and those have proven to suffer from the harsh operational environment of wind turbines (mainly static electricity discharge and lightning strikes).

- The industry has been quite reluctant to install structural health monitoring (SHM) systems for the blades, as this would require the adoption of alternative disruptive technologies which are often more expensive than conventional sensors.

- Turbine OEMs, operators and farm owners are not so much interested in processing raw condition monitoring data but rather in a traffic light system that allows the detection of criticality of defects.”

Resolution

The BladeSave project aim is to commercialise a novel solution, BladeSave, a fusion between a Fibre Optic Structural Health Monitoring System providing multi-sensing capability and blade management software linking the data from inspection and maintenance to the SHM data offering a comprehensive solution for wind turbine blade monitoring, repair and management.

The project objective is to reduce the risks related to blade failures and contribute to the growth and competitiveness of wind energy in the world’s energy markets by commercialising an innovative solution that will:

- Resolve the fundamental industry problems with current sensors caused by static electricity and lightning.

- Provide a competitive, comprehensive and reliable blade SHM system and link the results to a cloud-based software incorporating risk-based inspection data analysis to minimise inspection costs.

- Meet the stricter regulations which are to be imposed throughout the EU to implement of techniques/technologies which can ensure turbine reliability (Comply with the amended EN 50308).

- Provide the confidence for extending the life of old wind turbines.

Due to confidentiality agreements, results of the project deliverables will be published after project completion.

Ongoing project – Duration: 2 years (June 2017- June 2019)